Plow-Off Conveyors

1205

12 in. (305 mm)

1605 & 1608

16 in. (406 mm)

2405 & 2410

24 in. (610 mm)

1205

370 ft (113 m) per minute

1608

390 ft (119 m) per minute

1605 & 2405

370 ft (113 m) per minute

2410

325 ft (99.06 m) per minute

1205

120 ft (36.58 m)

1605

100 ft (30.48 m)

1608

200 ft (60.96 m)

2405

120 ft (36.58 m)

2410

400 ft (121.92 m)

1205

Up to 56 ft³ (1.58 m³) or 3700 lbs (1678 kg) per minute

1605

Up to 90 ft³ (2.55 m³) or 3700 lbs (1678 kg) per minute

1608

Up to 95 ft³ (2.69 m³) or 3900 lbs (1769 kg) per minute

2405

Up to 209 ft³ (5.91 m³) or 3700 lbs (1678 kg) per minute

2410

Up to 136 ft³ (3.85 m³) or 2400 lbs (1089 kg) per minute

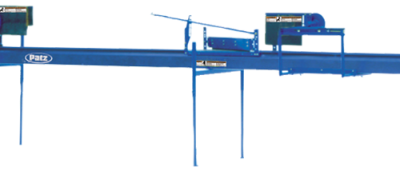

Plow-Off Conveyors

No two conveying applications are alike. Patz offers 14 intermediate, distribution, and cross-conveyor platforms with options in customization and capacity. Our light industrial conveyors will efficiently integrate your factory input and output product streams. Create windrows, fill storage bins and bays, or load transport. Discharge by side, section, or direction.

Standard Features & Options

ADJUSTABLE DECLINE ELBOW

Elevate materials and then convey level with an adjustable decline elbow (0° – 30°). The belt stays concave with a deep trough when passing over the elbow for maximum capacity.12 – 24 INCH BELTS

Choose 12-inch or 16-inch belt with concave, deep-trough design for maximum capacity. Customized lengths up to 120 feet.ONE-WAY FLOATING PLOW

The one-way floating plow drops feed off one side of the conveyor only, but can feed up to two lots different rations by using the 2-motor drive feeder.TWO-WAY FLOATING PLOW

The two-way floating plow can plow off either side of the belt and is also used if you wish to reverse the belt for adding material at various points. A remote electrical control is used to switch from one side of the storage area to the other. Feed up to four lots different rations by using a 2-motor drive feeder and a plow drive assembly. An optional deflector on the plow drops material closer to the conveyor.OPEN-PAN DESIGN

Open-pan design provides deep trough for extra capacity and reduces belt friction for lower power requirements. Fin pulley helps avoid buildup.ONE MOTOR DRIVE

One motor drives both the belt and plow (roller-chain drive) to feed one lot, or to feed two lots different materials when the bunk is split lengthwise. The plow reverses around a pulley automatically and smoothly at each end of the conveyor with continuous-loop cable drive.OPTIONAL PLOW DRIVE CONTROL BOX ASSEMBLY (24 in. units only)

Includes 1 HP motor, (2) proximity sensors, and a UL/cUL certified fiberglass control box with the ability to configure up to 10 separate lots. Control box is operated by an easy-to-use, 3 inch touch screen display.PROXIMITY SWITCH ASSEMBLY (24 in. units only)

Use with plow drive control box to add additional lots or plow park feature. Includes proximity switch and cable. Proximity sensors use a low voltage direct current (DC) system.